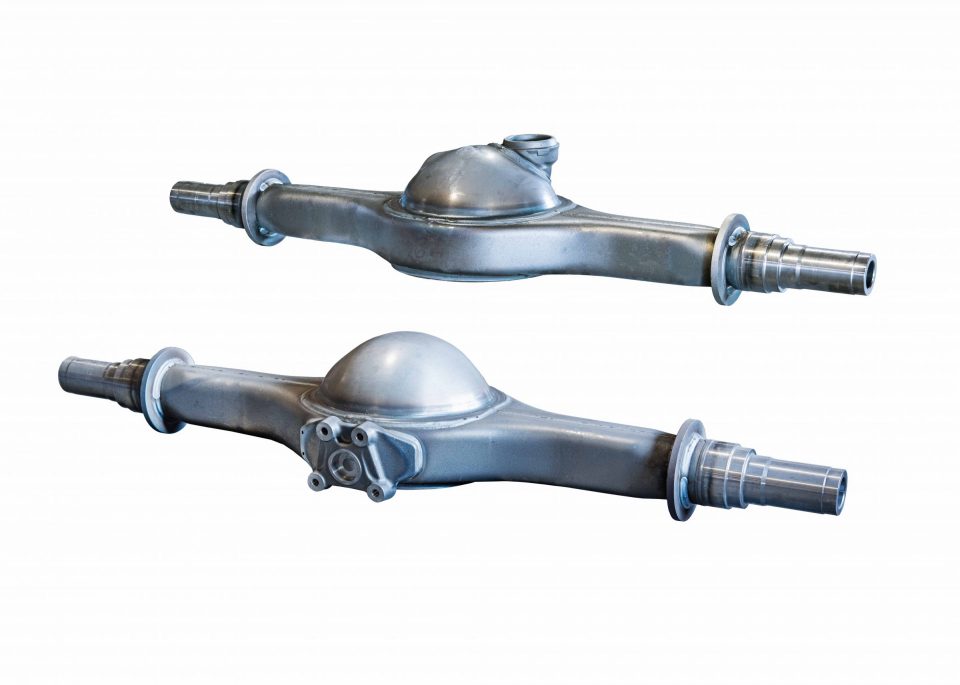

1:1 qualified Tandem axle bodies

We use the following materials for the production of the axle bodies:

- S355J2,

- S420MC

- 25CrMo4.

The welding of the axle bodies is performed by our advanced welding robots. This is extremely suitable for series production and delivers fast, consistent and efficient welding.

All shaft welds are 1: 1 qualified and are tested by a certified third party on the basis of a product certification. To ensure quality, our own quality department has also drawn up a (welding) quality plan.

Our customers place high demands on our quality system. We have all quality standards to meet these requirements. We are IS 9001 certified. We are also familiar with CP (Control Plans), PPAP (Production Part Approval Process) and FMEA (Failure Mode and Effects Analysis).

1:1 qualified FAN axle bodies

We use the following materials for the production of the axle bodies:

- S355J2,

- S420MC

- 25CrMo4.

The welding of the axle bodies is performed by our advanced welding robots. This is extremely suitable for series production and delivers fast, consistent and efficient welding.

All shaft welds are 1: 1 qualified and are tested by a certified third party on the basis of a product certification. To ensure quality, our own quality department has also drawn up a (welding) quality plan.

Our customers place high demands on our quality system. We have all quality standards to meet these requirements. We are IS 9001 certified. We are also familiar with CP (Control Plans), PPAP (Production Part Approval Process) and FMEA (Failure Mode and Effects Analysis).

High-quality parts

As a supplier of automotive parts, we set high standards for quality. We are always looking for improvements in the design and manufacturing process which will improve the assembly and reduces costs.

Our welders and operators are ASME IX and ISO 9606 certified and our welding procedures meet the EN 15614 standard.

Are you looking for a manufacturer and supplier of parts or assemblies for the process industry? We are happy to help you.

Happy to announce that we have successfully completed the VCA** certification process.

More and more customers asked and are asking us to support them during site activities like fitting, welding and installation of equipment like piping, pressure vessels and heat exchangers delivered by OMT.

Not having a VCA certification was in many cases an issue for our customers.

During this certification process, we lifted our company to a safer, healthier and more environmentally conscious organisation, able to partner with our customers from engineering up and including installation.

Complement to all our staff, specially to Machiel Mandersloot, as responsible QSHE engineer for the OMT organisation.

Another project ready for final shipment. For Munters Euroform Gmbh, we fabricated some Air Mist Eliminators for separation of liquid droplets from a process gas flow.

Material of construction is a corrosion resistant nickel-copper Alloy type 400 (2.4360).

Result is another happy customer, we don’t do it for less here at OMT.

Despite the current corona virus, OMT is still going strong. Just like all other companies, we are facing a lot of uncertainties. We have taken the necessary measures to continue our business as safe as possible and we remain positive here at OMT.

Below picture shows a hydro static test in progress performed a few days ago. Two adsorber vessels (twins) designed and fabricated by OMT. Design code ASME VIII div 1 with code stamp and severe cyclic service design case. MOC for these vessels is carbon steel.

Again a project well done, finished in time with a happy customer as a result. Goods ready for painting.

You can reach us by phone and/or e-mail and we will keep on partnering with you.

To all: take good care of yourself and your loved ones.

Ommeren Metaaltechniek has started with manufacturing a seperator vessel. The seperator vessel including internals will be used to seperate gasflows.

The design of the vessel will be according the ASME VIII div 1 and will also comply to the European PED 2014/68/EC guidelines for pressure vessels.

The complete vessel is manufactured out of stainless steel 304

In the video below you can see a part of the welding process on the seperator vessel

Ommeren Metaaltechniek has Cold Arc welding equipment available since February 2020.

This welding process is more efficient than other GMAW methods when the metal is thinner than 10 mm. The welding equipment detects a short circuit that sends a signal that causes the filler material to retract, cooling the seal time before each drop is placed. This leaves a smooth weld which is stronger than that of a hotter weld.

Recently we finished another great project, in which we fabricated several separator internals for a large refinery.

Several inlet devices, vertical vane packs for liquid/gas separation and some inlet sparger systems were fabricated by OMT.

Material of construction stainless steel, grade 316L, sour service application.

Engineering, manufacturing and welding professionals, partnering with you.